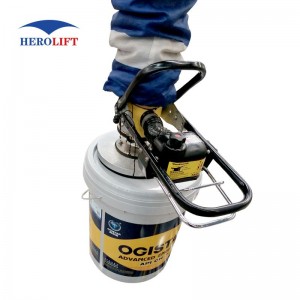

Pail lifting and handling Vacuuum lifter From pharmaceutical industry to the food and beverage industry

One of the main features of a vacuum drum elevator is its versatility. They are suitable for handling all types of materials commonly used in drum packaging - whether paper bags, plastic bags, burlap bags or burlap bags. No matter what the material, workers can rely on the vacuum roller hoist to provide a firm grip from the top or the side, ensuring a firm grip during lifting. This feature also allows them to lift drums overhead or deep into pallet racks, making it easier to efficiently stack and store drums.

In addition to being easy to operate, vacuum drum elevators offer significant advantages for packaging and logistics operations. Capable of safely lifting and transporting drums of various sizes and weights, these devices simplify the packaging process, saving time and reducing the risk of damage or spillage. Additionally, they enable the smooth movement of drums from one location to another, increasing the efficiency of logistics and warehouse operations.

CE certification EN13155:2003

China Explosion-proof Standard GB3836-2010

Designed according to German UVV18 standard

Lifting capacity: <270 kg

Lifting speed: 0-1 m/s

Handles: standard / one-hand / flex / extended

Tools: wide selection of tools for various loads

Flexibility: 360-degree rotation

Swing angle240 degrees

A large range of standardized grippers and accessories, such as swivels, angle joints and quick connections, the lifter is easily adapted to your exact needs.

| Type | VEL100 | VEL120 | VEL140 | VEL160 | VEL180 | VEL200 | VEL230 | VEL250 | VEL300 |

| Capacity(kg) | 30 | 50 | 60 | 70 | 90 | 120 | 140 | 200 | 300 |

| Tube Length(mm) | 2500/4000 | ||||||||

| Tube Diameter(mm) | 100 | 120 | 140 | 160 | 180 | 200 | 230 | 250 | 300 |

| Lift Speed(m/s) | Appr 1m/s | ||||||||

| Lift Height(mm) | 1800/2500

|

1700/2400 | 1500/2200 | ||||||

| Pump | 3Kw/4Kw | 4Kw/5.5Kw | |||||||

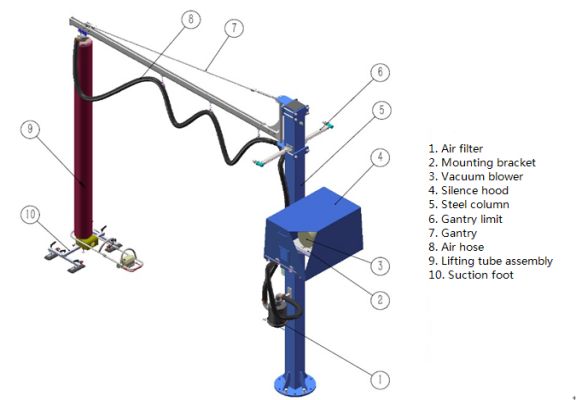

| 1,Air Filter | 6,Gantry limit |

| 2,Mounting bracket | 7,Gantry |

| 3,Vacuum blower | 8,Air hose |

| 4,Silence hood | 9,Lift tube assembly |

| 5,Steel Column | 10,Suction Foot |

Suction head assembly

•Easy replace •Rotate pad head

•Standard handle and flexible handle are optional

•Protect workpiece surface

Jib crane limit

•Shrinkage or elongation

•Achieve vertical displacement

Air tube

•Connecting blower to vacuum suction pad

•Pipeline connection

•High pressure corrosion resistance

•Provide security

Power control box

•Control the vacuum pump

•Displays the vacuum

•Pressure alarm

Since its establishment in 2006, our company has served more than 60 industries, exported to more than 60 countries, and established a reliable brand for more than 17 years.