Column Cantilever Vacuum Suction Crane – Laser cutting machine loading machine

In addition, this modern lifting equipment attaches great importance to safety. Post-cantilever vacuum suction cup cranes are equipped with state-of-the-art suction cup technology to ensure a firm grip on the panels during the lifting process. This minimizes the risk of accidents, such as a slipping or damaged board, protecting both workers and product.

The introduction of post-cantilever vacuum suction cup cranes has also had a wider impact on the entire manufacturing industry. It represents an important step in the automation and digitalization of production processes. By adopting this advanced technology, manufacturers can stay ahead of the competition and ensure efficient and sustainable production capabilities.

Almost everything can be lifted

With custom-made tools we can solve your specific needs. Please contact us for more information

1, Max.SWL1500KG

Low pressure warning

Adjustable suction cup

Remote control

CE certification EN13155:2003

China Explosion-proof Standard GB3836-2010

Designed according to German UVV18 standard

2, Large vacuum filter, vacuum pump, control box incl start / stop, energy saving system with automatic start/stop of vacuum, electronic intelligent vacuum surveillance, on/off switch with integrated power surveillance, adjustable handle,standard with equipped with bracket for quick attachment of lifting or suction cup.

3,A single person can thus quickly move up to 1 tonnes, multiplying productivity by a factor of ten.

4,It can be produced in different sizes and capacities according to the dimensions of the panels to be lifted.

5,It is designed using high-resistance, guaranteeing high performance and an exceptional lifetime.

| Serial No. | BLA400-6-T | Max capacity | Horizontal handling 400kg |

| Overall Dimension | 2160X960mmX910mm | Power input | AC220V |

| Control mode | Manual push and pull rod control absorption | Suction and discharge time | All less than 5 seconds; (Only the first absorption time is slightly longer, about 5-10 seconds) |

| Maximum pressure | 85%vacuum degree(about0.85Kgf) | Alarm pressure | 60%vacuum degree

(about0.6Kgf) |

| Safety factor | S>2.0;Horizontal absorption | Dead weight of equipment | 95kg(approximate) |

| Power failure

Maintaining pressure |

After power failure, the holding time of the vacuum system absorbing the plate is >15 minutes | ||

| Security alarm | When the pressure is lower than the set alarm pressure, the audible and visual alarm will alarm automatically | ||

Suction pad

•Easy replace •Rotate pad head

•Suit various working conditions

•Protect workpiece surface

Power control box

•Control the vacuum pump

•Displays the vacuum

•Pressure alarm

Vacuum gauge

•Clear display

•Color indicator

•High-precision measurement

•Provide security

Quality Raw Materials

•excellent workmanship

•long life

•High quality

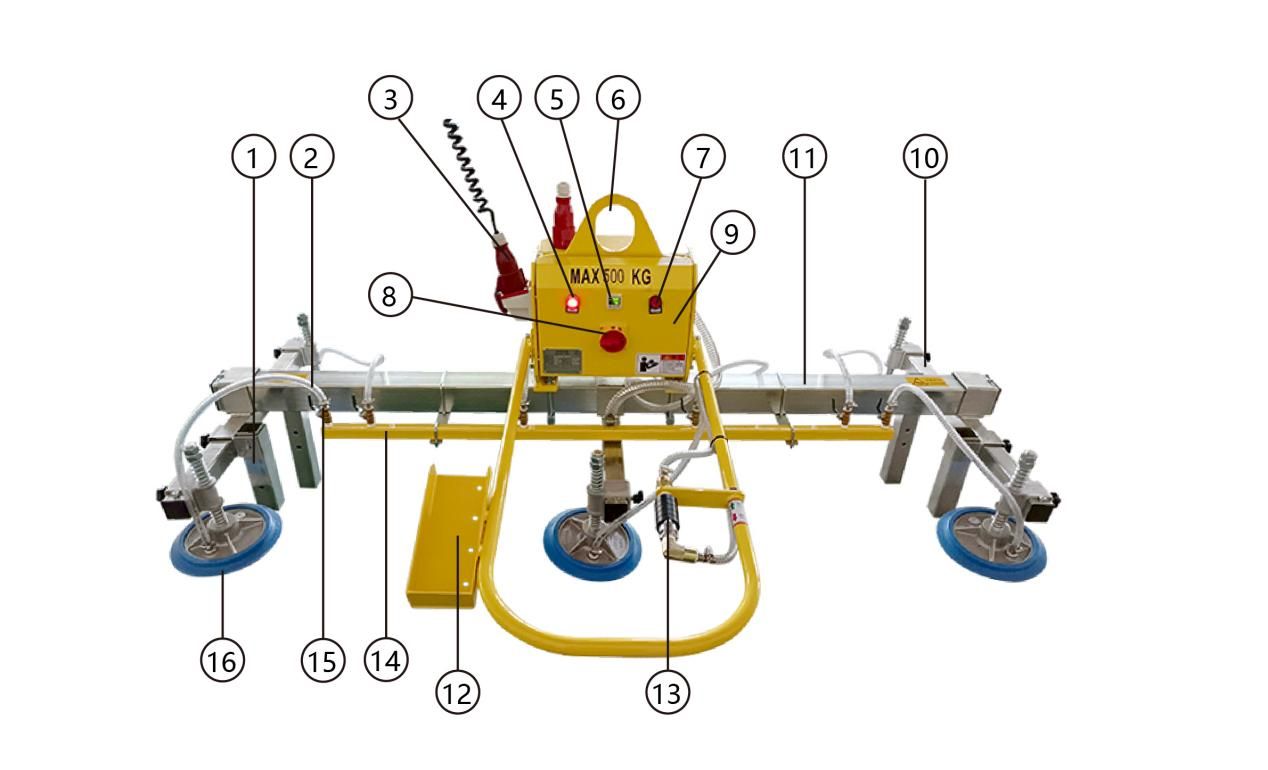

| 1 | Supporting Feet | 9 | Vacuum Pump |

| 2 | Vacuum Hose | 10 | Beam |

| 3 | Power connecter | 11 | Main Beam |

| 4 | Power light | 12 | Remove Control Tray |

| 5 | Vacuum Gauge | 13 | Push-Pull Valve |

| 6 | Lifting ear | 14 | Shunt |

| 7 | Buzzer | 15 | Ball Valve |

| 8 | Power Switch | 16 | Suction Pads |

Safety tank integrated;

Adjustable suction cup;

Suitable for occasions with large size changes

Imported oil-free vacuum pump and valve

Efficient, safe, fast and labor-saving

Pressure detection ensure safety

The suction cup position be closed manually

Design conforms to CE standard

This equipment is widely used for laser feeding.

Aluminum Boards

Steel Boards

Plastic Boards

Glass Boards

Stone Slabs

Laminated chipboards

Metal processing industry

Since its establishment in 2006, our company has served more than 60 industries, exported to more than 60 countries, and established a reliable brand for more than 17 years.