Best Price on 30kg-100kg Intelligent Vacuum Tube Lift Vacuam Suction Cup Pad Lifter

We’re commitment to offer you the competitive price ,remarkable products excellent, also as fast delivery for Best Price on 30kg-100kg Intelligent Vacuum Tube Lift Vacuam Suction Cup Pad Lifter, We welcome shoppers everywhere in the word to call us for long run small business associations. Our solutions are the top. Once Selected, Excellent Forever!

We’re commitment to offer you the competitive price ,remarkable products excellent, also as fast delivery for China Vaculex Type and Becker Vacuum Pump, You can always find the products and solutions you need to have in our company! Welcome to inquire us about our product and anything we know and we can help in auto spare parts. We’re looking forward to work with you for a win-win situation.

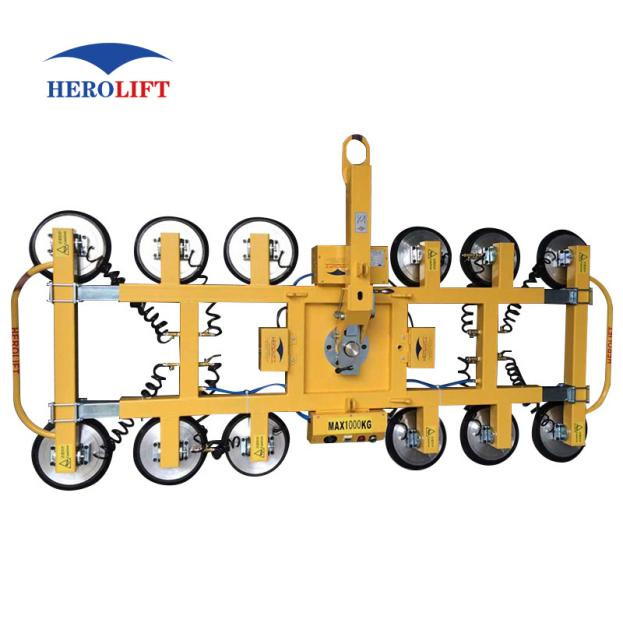

1. Max.SWL 65KG

Low pressure warning.

Adjustable suction cup.

Remote control.

CE certification EN13155:2003.

China Explosion-proof Standard GB3836-2010.

Designed according to German UVV18 standard.

2. Easy to customize

Thanks to a large range of standardized grippers and accessories. such as swivels. angle joints and quick connections. the lifter is easily adapted to your exact needs.

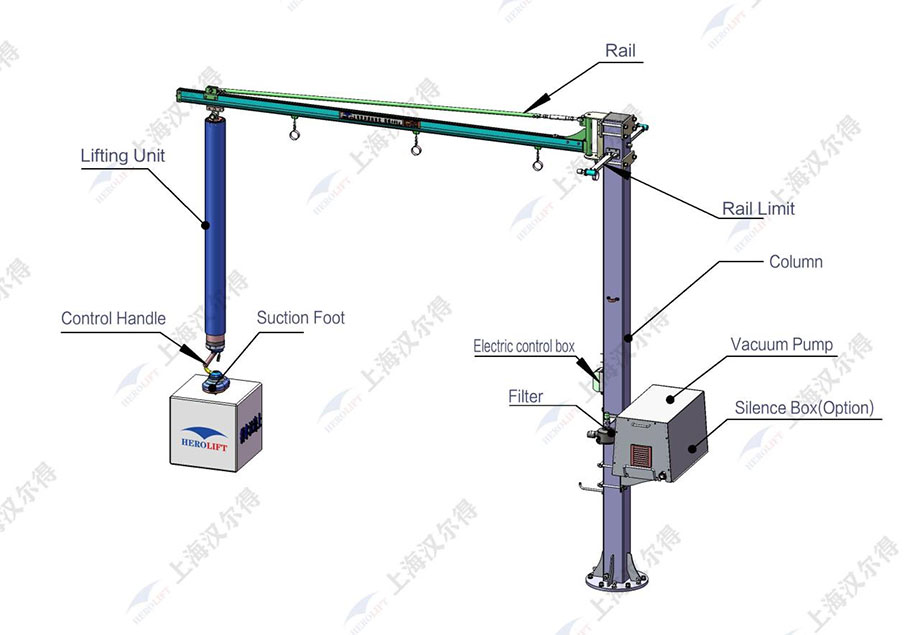

3. Ergonomic handle

The lifting and lowering function is regulated with an ergonomically designed control handle. Controls on the operating handle make it easy to adjust the lifter’s stand-by height with or without a load.

4. Energy-saving and fail-safe

The lifter is designed to ensure minimum leakage. which means both safe handling and low energy consumption.

+ For ergonomic lifting up to 65 kg.

+ Rotate in horizontal 360 degrees.

+ Swing angle 270.

| Serial No. | VCL120U | Max capacity | 40kg |

| Overall Dimension | 1330*900*770mm | Vacuum equipment | Manually operate the control handle to suck and place the workpiece |

| Control mode | Manually operate the control handle to suck and place the workpiece | Workpiece displacement range | Minimum ground clearance150mm,Highest ground clearance1500mm |

| Power supply | 380VAC±15% | Power input | 50Hz ±1Hz |

| Effective installation height on site | Greater than 4000mm | Operating ambient temperature | -15℃-70℃ |

| Type | VEL100 | VEL120 | VEL140 | VEL160 | VEL180 | VEL200 | VEL230 | VEL250 | VEL300 |

| Capacity (kg) | 30 | 50 | 60 | 70 | 90 | 120 | 140 | 200 | 300 |

| Tube Length (mm) | 2500/4000 | ||||||||

| Tube Diameter (mm) | 100 | 120 | 140 | 160 | 180 | 200 | 230 | 250 | 300 |

| Lift Speed(m/s) | Appr 1m/s | ||||||||

| Lift Height (mm) | 1800/2500 | 1700/2400 | 1500/2200 | ||||||

| Pump | 3Kw/4Kw | 4Kw/5.5Kw | |||||||

| Type | VCL50 | VCL80 | VCL100 | VCL120 | VCL140 |

| Capacity (kg) | 12 | 20 | 35 | 50 | 65 |

| Tube Diameter (mm) | 50 | 80 | 100 | 120 | 140 |

| Stroke (mm) | 1550 | 1550 | 1550 | 1550 | 1550 |

| Speed(m/s) | 0-1 | 0-1 | 0-1 | 0-1 | 0-1 |

| Power KW | 0.9 | 1.5 | 1.5 | 2.2 | 2.2 |

| Motor Speed r/min | 1420 | 1420 | 1420 | 1420 | 1420 |

Protection against power failure: ensure that the absorbed material will not fall under power failure.

Leakage protection: prevent personal injury caused by leakage, and the vacuum system is well insulated as a whole.

Protection of current overload: that is, to prevent damage to vacuum equipment due to abnormal current or overload.

Stress test, in-plant installation test and other tests to ensure that each set of equipment leaving the factory is safe and qualified.

Safe adsorption, no damage to the surface of material box.

For sacks, for cardboard boxes, for wooden sheets, for sheet metal, for drums, for electrical appliances, for cans, for baled waste, glass plate, baggage, for plastic sheets, for wood slabs, for coils, for doors, battery, for stone.

Vacuum tube lifts have become an ingenious solution for various industries, offering a wide range of capabilities to handle raw materials, round cans, bagged goods, parcels, cartons, luggage, doors and windows, OSB, wood products and many other items. Due to their versatility, these innovative lifts have become indispensable tools in warehouse operations, assembly line production and high-volume product handling needs.

Vacuum tube lifts have become an ingenious solution for various industries, offering a wide range of capabilities to handle raw materials, round cans, bagged goods, parcels, cartons, luggage, doors and windows, OSB, wood products and many other items. Due to their versatility, these innovative lifts have become indispensable tools in warehouse operations, assembly line production and high-volume product handling needs.

One of the main benefits of vacuum lifters is their ability to significantly increase productivity while saving time and money. By eliminating constant starts and stops that disrupt workflow, these high-performance machines ensure a seamless and streamlined material handling process. This uninterrupted workflow not only optimizes productivity, but also reduces worker fatigue and improves overall operational efficiency.

In addition, vacuum lifters actively contribute to load protection by eliminating traditional clamps and slings. Minimize damage caused by pinched or hanging items and ensure safe transportation of fragile or delicate cargo. As a result, businesses can mitigate the financial losses caused by damaged products, increase customer satisfaction, and safeguard their reputation.